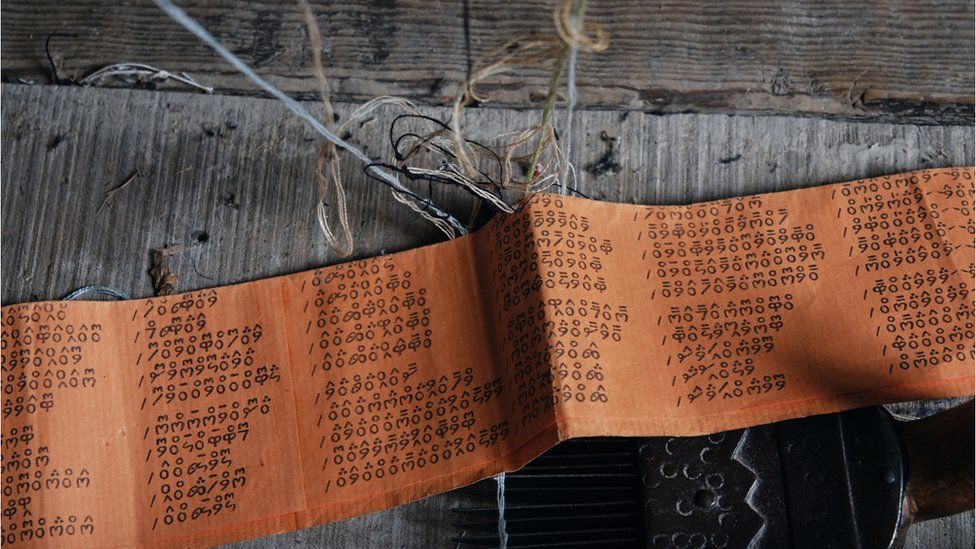

Called talim, the code has been used for hundreds of years to design carpets and convey information to weavers.

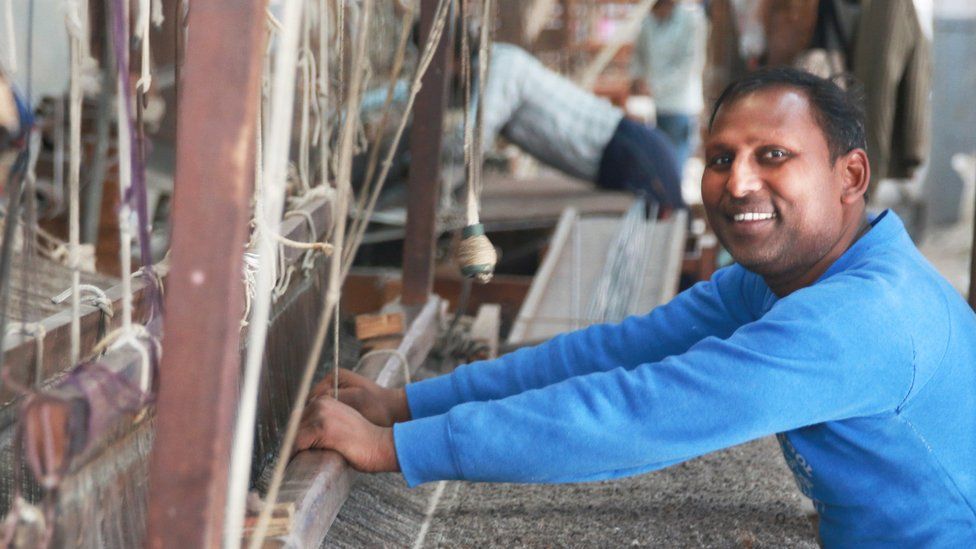

From the age of eight, and following in the footsteps of his father, Mohammad Rafiq Sofi has been weaving carpets using talim designs.

“It took me five years to learn how to weave properly,” says Mr Sofi, now 57.

Much has changed during his half century in the industry. Mr Sofi says that in the early days it could take more than six months to complete a carpet.

To start the process, a designer would draw up a carpet. A talim expert would then encode that design, and in small sections send it off for weaving.

Those chunks of code would be translated for Mr Sofi and weavers like him, showing them where to knot each thread and which colour to use.

Each section would only represent a small piece of the carpet, so hundreds would be needed for the whole carpet, with much back and forth between the designers and weavers.

The process made mistakes difficult to spot and time-consuming to correct.

But these days computer software has streamlined the process and Mr Sofi can finish a carpet in six weeks.

The weaving and knotting is still done by hand, but now computer software handles the design and creation of the talim code. It means Mr Sofi can see the whole design at once, instead of just small sections.

Any potential problems can be spotted in advance, cutting down on time-consuming errors.

“This innovation in handmade carpets is not to disrupt the essence of artistic carpets, it’s just to speed up the process – designs being available now at a speed,” says Mehmood Shah, the director of Handloom & Handicrafts for the government of Jammu and Kashmir.

The latest innovation comes from technology firms that are applying artificial intelligence to the process.

Aby Mathew is chief operating officer at International Virtual Assistance, a computer software firm that specialises in analysing data.

His company is training an artificial intelligence (AI) system to understand the talim code by showing it pictures of carpets and lines of talim code.

The AI is still being developed and the process will still require a human to write the code, but Mr Mathew says it should speed up manufacturing by decoding the talim instructions for the weavers.

“Weavers will be able to try out new patterns, update classic themes to suit contemporary tastes, and produce one-of-a-kind, custom carpets,” says Mr Mathew.

As India grows richer he sees an increasing demand for carpets that the traditional industry will struggle to meet.

“The tastes of customers are evolving, with a growing desire for carpets that are fashionable, long-lasting, and low maintenance. Conventional carpet-making techniques are frequently labour-intensive and sluggish – they might not be able to satisfy these needs,” says Mr Mathew.

Aditya Gupta founded Rug Republic 32 years ago, it now employs around 5,000 people and makes up to 15,000 rugs per month. He says the Indian rug and carpet industry is facing stiff competition from rivals in Turkey and China and needs to keep up with the latest manufacturing techniques.

“Innovation is important in every industry – without it, we die,” he says.

“The Indian carpet industry is an interesting case, where it is not only about moving forward with new tech, but rather moving the old and the new hand in hand.

“The innovation now is oriented towards creating designs that cannot be copied by machines while still using traditional techniques.”

At Rug Republic, new tech has been introduced for the design, washing and drying of carpets and for monitoring moisture levels. As well as the traditional wool, materials like recycled jeans, cotton and leather have been experimented with.

Despite all the innovation, Mr Gupta still values the old methods.

“The manufacturing side of things still needs to be traditional and handmade as that is the main charm the consumers seek.”

The industry has also been helped by an official tagging system which identifies a genuine hand-knotted Kashmiri carpets.

By scanning a QR code buyers can verify the carpet designer and how it was made.

“If the [Handicrafts] department hadn’t taken this step, maybe this trade in handwoven carpets would have died in a few years,” says carpet designer, Shahnawaz Ahmad.

That would have been a blow as the industry is an important part of the local economy. It employs around 50 thousand workers in Jammu and Kashmir, who collectively produce rugs and carpets worth around £36m ($28m) a year.

The developments in carpet making have given hope to old-timers like Feroz Ahmad Bhat, who has been weaving carpets for the past thirty years.

“In my early days, our earnings were good and a lot of people were involved with this work. Then a time came when wages were very low. But now new designs have been introduced and this work has picked up pace again. Now it’s flourishing again.”